Download scientific diagram Brief diagram for glove manufacturing process. After heating and cooling the liquid.

They may be further differentiated according to kind of textile gauge number of the fabric lining type of rubber and treatment of.

. User Interface Selectable multichannel MI compact CI or a web. Steel Core gloves are cut and abrasionresistant and are often used for meatpoultry processing glass handling metal fabrication automotive manufacturing as well as being used in the paper industry. 51 Production Process Flow The process of gloves manufacturing starts with the receipt of specification sample of gloves from the customer and or design developed by the designing department.

Rubber Gloves Nitric Acid 10 CB XA-A up to 140 Calcium Carbonate-AC B A Calcium Nitrate A-B up to 212 B up to 212 B up to 212 B up to 212 X A up to 140 Latex-AC-A Excellent Type B Good C Fair to Poor X Not Recommended No Data Available Data limited to concentration and or temperature F shown. Powder free gloves go through an extra process of chlorinating the gloves to ease. Enhancement of sigma level in the manufacturing of furnace nozzle through DMAIC.

Certain latex proteins carried over into the finished product by inadequate. Glove coating and manufacturing process Download PDF Info Publication number. Lightly powdered latex gloves are produced with a food grade corn starch powder creating donning easier particularly when hands are wet.

The business plan is to Natural rubber to Hand. The present invention relates also to gloves obtainable by said process. Traders and international buyers.

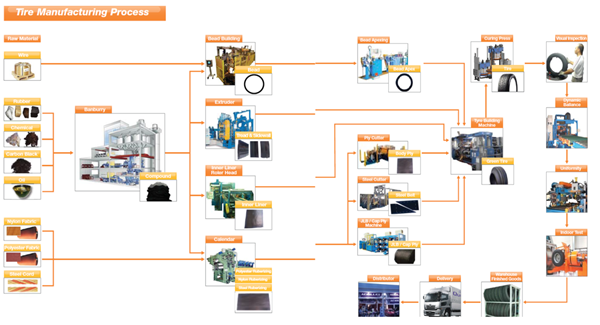

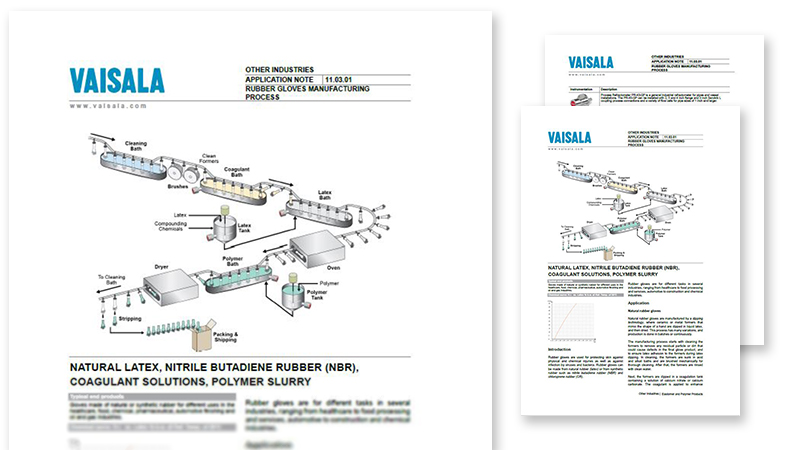

A Case Study of Defects Reduction in a Rubber Gloves Manufacturing Process by Applying Six Sigma Principles and DMAIC Problem Solving Methodology. 1 raw material testing 2 compounding 3 dipping 4 leaching and vulcanizing 5 stripping and tumbling quality c6 ontrol and 7 packing. The demand for surgical gloves is influenced by several related factors.

Instrumentation Description K-Patents Process Refractometer PR-43-GP is a general industrial refractometer for pipes and vessel installations. Rubber gloves manufacturing processes Rubber gloves manufacturingprocesses and particularly the process studied and investigated in this paper are generally comprised of seven steps namely. An Overview 14 Aug 2018 Surface Treatment of Rubber Glove 20 Sep 2018 Vulcanization of Rubber Glove 16 Oct 2018 Design and Development Change and Process Validation Outlines For enquiries please contact Ms.

Unlocking the Secret of Bio-additive Components in Rubber. There are many stages to ensure the gloves which are delivered to your door meet the highest standard and cleanroom grade. These formers were then immersed in a container containing NBR.

They are immersed in a solution of calcium carbonate and calcium nitrate and dried. Initially at first the manufacturing machine removes any stains and previous elements from the formers shaped like a hand. These gloves should meet the requirements for a surgeons glove as well as additional 510k and labeling recommendations described in the following paragraphs.

Fashion Gloves manufacturing unit is assumed to operate as a sole-proprietorship. Reported is related to NR latex products especially gloves. 229920001971 elastomer Polymers 0000 claims abstract description 79.

There are about 200 latex gloves manufacturers in India in small and medium scale sectors. BioClean cleanroom glove manufacturing isnt a quick or simple process. 17 Apr 2018 Manufacturing of Medical Glove to Meet Regulatory and Customer Requirements 10 Jul 2018 Glove Manufacturing Process.

Disposable gloves can be either powdered or powder-free. Natural rubber latex has consistently been the most satisfactory raw material for the manufacture of gloves. The factory has a clean hygienic dust free manufacturing environment.

Intended to be worn by operating room personnel to protect a surgical wound. The PR-43-GP can be installed with 2 3 and 4 inch flange and 3 inch Sandvik L coupling process connections and a variety of flow cells for pipe sizes of 1 inch and larger. Stage 1 Glove Former Preparation.

A surgical surgeons glove is a device m ade of natural or synthetic r ubber. 238000004519 manufacturing process Methods 0000 title description 10. Gloves that will provide a barrier of protection from infectious organisms are an essential feature of medical practice for the protection of both patients and medical personnel.

Full PDF Package. The manufacturing environment and process has been designed to achieve the critical in-built quality that is necessary in a MEDICAL DEVICE as per GMP requirements. Powdered gloves offer the advantage of easier donning even with sweaty hands.

The present invention relates to a blend of foam latex and to a manufacturing process to produce gloves from said blend. The plant is completely closed and the factory has controlled exit and entry points with positive air. BioClean glove formers are meticulously prepared going through numerous acid water and alkaline washes as.

As the surgical gloves are consumed by surgeons during surgeries the demand is influenced by the following factors. The blends of the invention comprises synthetic andor natural latex and at least a foaming agent selected from the group comprising disodium n- octadecylsulfosuccinamate sodium dihexyl. 13 Manufacturing Process 131 Knitting of gloves In gloves making process yarn packages are used as a feed material.

239000011248 coating agent Substances 0000 claims abstract description 160. In general powder free natural rubber gloves are more skin tolerable as they contain less chemical residues and water soluble protein thanks to the manufacturing process. Where not shown is.

Download Free PDF Download PDF Download Free PDF View PDF. Dental Surgeons Glove. - Prevalence of diseases requiring surgery.

The manufacturing process for Rubber Gloves involves very few steps due to the automatic machines and the machine connects all the forms in moving chain to dip and clean in different tanks of latex and chemicals for continuous process till the packing of Gloves. Rubber gloves may be divided into five types. A sim-ilar wide variation was reported by Yunginger et al13 who measured the EP level by a modified triketohydrindene.

A survey of EP levels in medical gloves with the use of the modified Lowry test12 revealed that glove EP levels could vary from as low as 1000 µgg. Latex gloves are on the market in each gently powdered and powder free choices in a very variety of thicknesses. Here are the manufacturing process.

Rubber gloves have been developed for specific usage environments or requirements and there are hence many diverse kinds of rubber glove here classified according to type in Table 1. Modified and adapted source 33 from publication.

Pdf A Case Study Of Defects Reduction In A Rubber Gloves Manufacturing Process By Applying Six Sigma Principles And Dmaic Problem Solving Methodology Semantic Scholar

Pdf A Case Study Of Defects Reduction In A Rubber Gloves Manufacturing Process By Applying Six Sigma Principles And Dmaic Problem Solving Methodology Semantic Scholar

Pdf Unlocking The Secret Of Bio Additive Components In Rubber Compounding In Processing Quality Nitrile Glove

Nitrile Gloves Manufacturer Nitrile Examination Gloves Supplier

Pdf Leaching A Critical Factor In Processing Of Rubber Examination Gloves

Dipping Baths In Rubber And Medical Gloves Manufacturing Vaisala

Environmental Impacts Of Examination Gloves Made Of Natural Rubber And Nitrile Rubber Identified By Life Cycle Assessment Patrawoot 2021 Spe Polymers Wiley Online Library

Pdf Production Method Market Trend Of Rubber Gloves Semantic Scholar

Occupational Exposure And Ill Health Among Workers During Latex Glove Manufacturing In Thailand Semantic Scholar

Emerging Crosslinking Techniques For Glove Manufacturers With Improved Nitrile Glove Properties And Reduced Allergic Risks Sciencedirect

Pdf A Six Sigma And Dmaic Application For The Reduction Of Defects In A Rubber Gloves Manufacturing Process

The Manufacture Of Gloves From Natural Rubber Latex Journal Of Allergy And Clinical Immunology

Pdf A Six Sigma And Dmaic Application For The Reduction Of Defects In A Rubber Gloves Manufacturing Process